Box-making machines and printing machines - Shinko Super Alpha

Flexo Folder Gluer manufacturing has evolved as markets changed for over 50 years.

SHINKO has always been researching & developing on fixed-type FFG with new design idea that is not bound by industry concepts.

SHINKO continually pursues the small lot, labor saving and high accuracy, and we developed the state-of-the-art machine "SHINKO SUPER α" .

Specification

| Machine specification | 920 type | 921 type | 1122 type | |

|---|---|---|---|---|

| Maximum machine speed | (sheets/min.) | 350 | 350 | 300 |

| Maximum sheet size (A box) | (mm) | 880×2,000 | 880×2,100 | 1,050×2,200 |

| Minimum sheet size (A box) | (mm) | 230×695 | 230×695 | 260×755 |

| Gluer bridge minimum size | (mm) | 330 | 330 | 360 |

| Maximum sheet size (flat size) | (mm) | 880×1,100 | 880×1,100 | 1,050×1,200 |

| Minimum sheet size (flat size) | (mm) | 230×600 | 230×600 | 260×600 |

| Counter width | (mm) | 1,400 | 1,400 | 1,500 |

| Maximum print area | (mm) | 820×1,900 | 820×2,000 | 1,020×2,100 |

| Maximum printing plate length | (mm) | 880 | 880 | 1,050 |

| Glue flap width | (mm) | 35 | 35 | 35 |

| Minimum box height | (mm) | 50 | 50 | 50 |

| Required power | (kw) | approx.85 | approx.85 | approx.110 |

| Approximate weight | (kg) | approx.45,000 | approx.50,000 | approx.71,000 |

| Machine specification | 1125 type | 1227 type | 1230 type | |

|---|---|---|---|---|

| Maximum machine speed | (sheets/min.) | 300 | 250 | 250 |

| Maximum sheet size (A box) | (mm) | 1,050×2,500 | 1,210×2,700 | 1,210×3,000 |

| Minimum sheet size (A box) | (mm) | 260×755 | 290×875 | 290×875 |

| Gluer bridge minimum size | (mm) | 360 | 360 | 360 |

| Maximum sheet size (flat size) | (mm) | 1,050×1,200 | 1,210×1,700 | 1,210×1,700 |

| Minimum sheet size (flat size) | (mm) | 260×600 | 290×600 | 290×600 |

| Counter width | (mm) | 1,500 | 2,000 | 2,000 |

| Maximum print area | (mm) | 1,020×2,400 | 1,100×2,600 | 1,100×2,900 |

| Maximum printing plate length | (mm) | 1,050 | 1,210 | 1,210 |

| Glue flap width | (mm) | 35 | 35 | 35 |

| Minimum box height | (mm) | 50 | 50 | 50 |

| Required power | (kw) | approx.110 | approx.120 | approx.120 |

| Approximate weight | (kg) | approx.74,000 | approx.82,000 | approx.90,000 |

Functions LIst

| Unit name | Specifications and Functions | Standard equipment | Optional equipment |

|---|---|---|---|

| Feeding Unit | Roll less feeder | ○ | |

| Gate-shaped side jogger | ○ | ||

| Auto return to “zero” position | ○ | ||

| Test sheet running device | ○ | ||

| Sheet jam detector | ○ | ||

| Oblique sheet feeding sensor | ○ | ||

| First sheet setting device | ○ | ||

| Skip feed | ○ | ||

| Printer (Printing Unit) |

Fixed type printer | ○ | |

| Chamber doctor blade system | ○ | ||

| 2 roll type | ○ | ||

| Multiple colors | ○ | ||

| Print from upper | ○ | ||

| Motorized lateral adjustment of plate cylinder | ○ | ||

| Plate cylinder auto return to “zero” position | ○ | ||

| Automatic printing plate winding device | ○ | ||

| Automatic ink supply cleaning device | ○ | ||

| Ink flow monitoring buzzer | ○ | ||

| Automatic ink touch device | ○ | ||

| Ceramic anilox roll | ○ | ||

| Ink bath teflon coating | ○ | ||

| Teflon-coated ink supply area | ○ | ||

| Equipped with 1 ink can | ○ | ||

| Equipped with 2 ink scans | ○ | ||

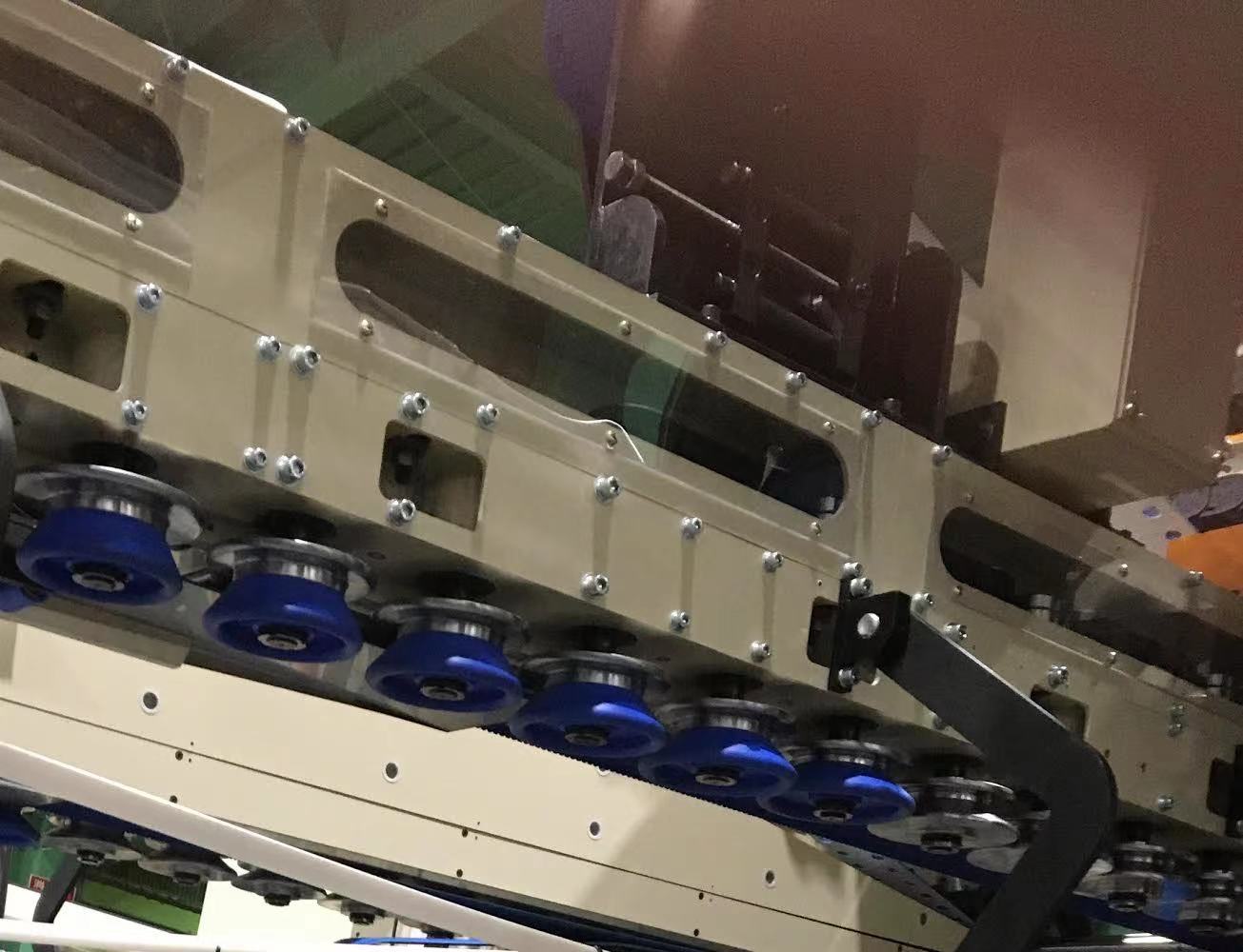

| Carrying Unit | Carrying belt | ○ | |

| Carrying belt center suction | ○ | ||

| Slotter Unit | Double Slotter | ○ | |

| Double Creaser | ○ | Large diameter crushing roll | ○ |

| Large diameter creasing roll | ○ | ||

| Automatic adjustment of the joint flap length | ○ | ||

| Glue joint waste removing fan | ○ | ||

| Die Cutting Unit | cutting up or cutting down | ○ | selectable |

| Pin type stripping system | ○ | ||

| One-touch hand hole cutter | ○ | ||

| Anvil polishing grinder type | ○ | ||

| Forming Unit | Forming roller | ○ | |

| Upper suction belt | ○ | ||

| Glue roll | ○ | ||

| Tube type glue pump | ○ | ||

| One-touch glue pot attachment/detachment (When glue cover is selected) | ○ | ||

| Double glue tank | ○ | ||

| Resin forming bar | ○ | ||

| Glue gun system | ○ | ||

| Lower edge independent movement | ○ | ||

| Electric gap adjustment of gluer top conveying roller | ○ | ||

| Upper dust mill & fan | ○ | ||

| Upper and lower dust mill & fan | ○ | ||

| Left and right independent lower forming belt | ○ | ||

| Automatic centering of resin forming bar | ○ | ||

| Counting Unit | Batch counter | ○ | |

| Upper and lower discharge belt | ○ | ||

| Large fan for sheet holding (electric wind direction adjustment) | ○ | ||

| CNC | Main control system by touch panel | ○ | |

| Teaching function | ○ | ||

| Uninterruptible power system | ○ | ||

| Communication to the production control system | ○ | ||

| Communication with various inspection devices | ○ | ||

| Large display | ○ |

Features & Functions

Feeding Unit

Gate-shaped side jogger

A large gate-shaped side jogger surely aligns sheet edge.

Test sheet running device

After automatically accelerating the machine, only one sheet is fed.

Sheet jam detector

Sheet jams cause machine damage. A sensor detects jams and automatically stops the machine.

Detection device for misaligned sheet feeding

Detect misaligned sheet feeding and stop feeding.

First sheet setting device (option)

After the lot change, a small stack of sheets is automatically fed to the feeder.

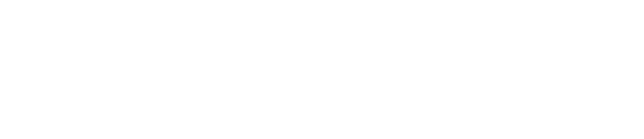

Printer (Printing Unit)

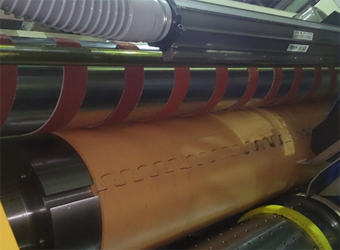

Fixed type printer

Unit fixed type, the plate cylinder raises and downs.

Each unit is connected by the carrying belt, the plate cylinder and ink roll can be raised about 100mm above the sheet pass line. The plate cylinder of the not-in-use printers can be raised for changing printing plate, or prepare for the next order, even while the machine is running. It shortens the setup time significantly, and reduces the work.

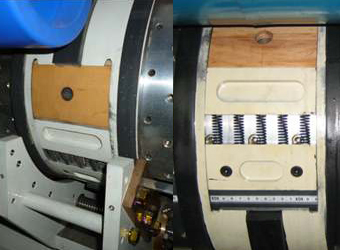

Chamber doctor blade system (Standard)

The doctor chamber type is the standard specification. Shinko's unique shape of the chambered doctor blade system ensures sharp and high-quality print images. A 2-roll type for varnishing and solid printing is also available.

Multi-color printing

Depending on the combination of printing units, it is also possible to handle multiple colors from 1 color to 4 colors or more.

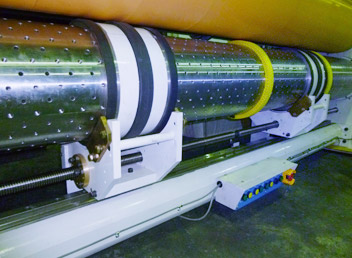

Anilox roll (selectable)

Carrying Unit

Carrying belt system

High-strength timing belts hold the left and right edges of the sheet between the top and bottom to convey the sheet, so even if the sheet is warped, it can be stably conveyed.

Carrying belt center suction

Since the sheet is sucked at the center of the carrying system, misalignment can be prevented.

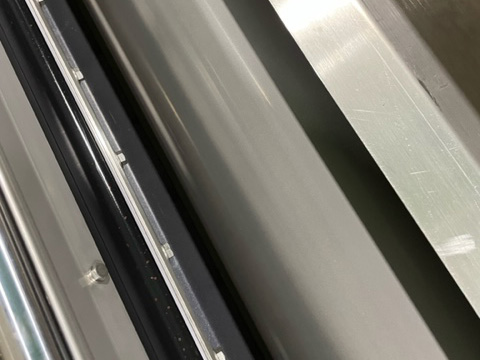

Slotting Unit

Double Slotter

By adopting Double Slottert, skip feed can also reduce the frequency of attachment and detachment of blades.

Double Creaser

Creasing and crushing shafts with large diameter facilitate stable joint accuracy.

Creasing roll

Two types of creasing roll can be attached, it is possible to deal with splitting line on the sheets.

Die Cutting Unit

Soft type Die Cutter

The "soft cut" serrated blade is used for the die cutting, and the anvil is wrapped with urethane. This is effective for preventing scraps of air vents in fruits and vegetables boxes. It can be operated under high speed and mass-produce that is difficult for press die cutter. There is also substantial improvement in scatter of scraps.

Handhole one-touch mechanism

Wooden cutting dies are easily attached with rolls.

Pin Stripping

Inserted pin on the roll push the scraps downward and eject them.

Anvil polishing - grinder type (option)

The asperity on the anvil roll that occurs in the production process is polished with a special roll to make it smooth.

Anvil polishing - cutting type (option)

A special shaped blade cuts the anvil roll to make it uniform.

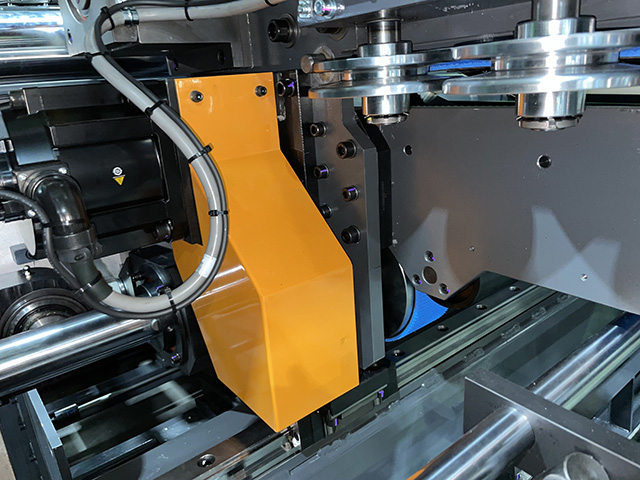

Forming Unit

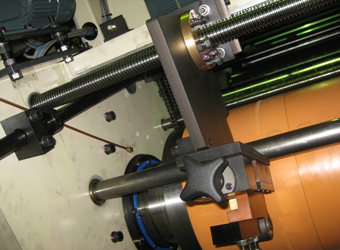

Forming roller

Shinko's forming roller system has patented in seven major countries in the world, and it produce boxes with high joint accuracy.

Glue roll

Upper belt with suction

Sheets are sucked with upper forming belt by suction fan, it enhances the convey performance.

Independent servo driven lower belt

Electric gap adjustment of lower edge

By moving only the lower edge independently, various settings can be adjusted according to the sheet types.

Glue gun system (option)

Glue pot can be one-touch installed and removed.

Counting Unit

Batch counter

It counts for each bundled in a set quantity. It can accurately count the number of sheets.

Excellent conveyor (option)

Sheets ejected from folding unit are conveyed to down stack part in backward of counter unit.

Then, sheets are ejected to proper way(operation side/drive side) for the next process.

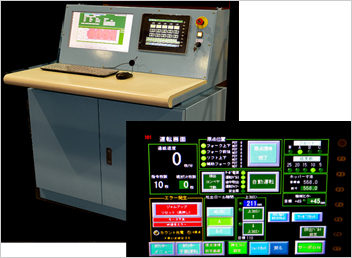

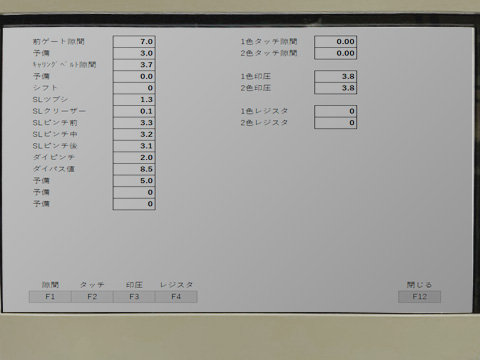

CNC

Main control system

Equipped with dedicated flexo gluer software that has been developed and improved specially, enabling accurate work in a short setting time.

Teaching function

Machine learns the each settings for sheets and products, so resetting for same order is unnecessary.

Large display (option)

The large display shows machine status. (machine speed, set up time etc)

Network communication (option)

Send machine setting data to peripherals, and pass data with various management systems.

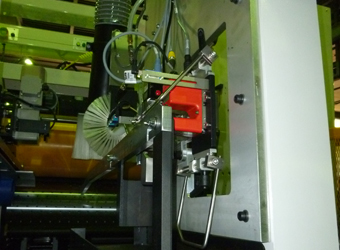

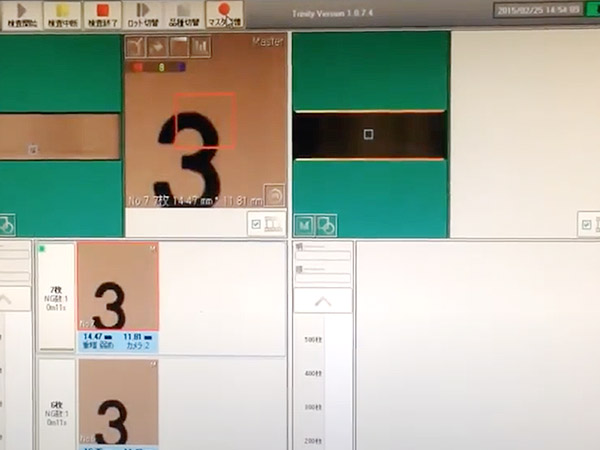

Visual Detection Device

Detection for printing, gluing, contamination, etc. (both sides)

Simultaneous detection of both sides is possible. The inside can also be inspected, it is ideal for the food-related industry.

Device construction example