Visual Detection Device(both sides)

Features of image equipment (both sides) for printing, gluing, contamination, etc.

This is a "double-sided inspection device" that can be additionally installed, enabling image inspection of the inside of cardboard boxes as well.

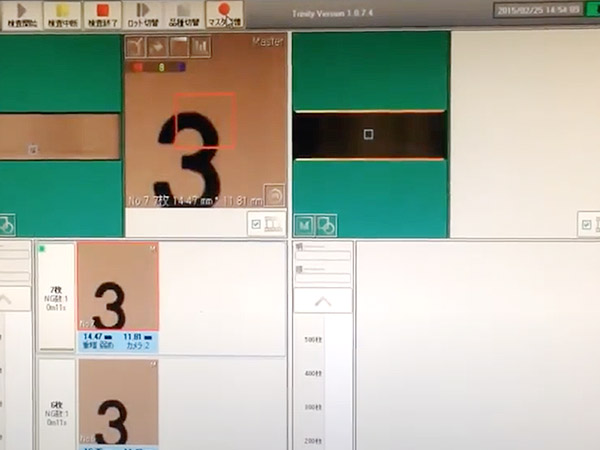

No-mask inspection method

Due to the DAC original inspection method, there is no uninspected area in the inspection section.

Newly developed defect circuit improves inspection accuracy.

Character-only, barcode-only, and periodic defect detection circuit improve inspection accuracy and prevent defect outflow.

Gallery for product traceability

Inspection history can be saved in the digital image filing device Gallery, and past inspection results can be viewed easily with images.

Yield is improved by the pattern automatic extraction function

By automatically cutting out the printing part and the texture part, normal inspection for the printing part, weak inspection for the texture part, and strong inspection for the bar code part are performed. It can stably inspect the printing defections.

Ultra-bright LED system (developed in-house)

In-house developed ultra-bright LED lighting with excellent contrast is used.

Uniform illuminance is achieved by matching the color temperature of each LEDI chip.

Easy operation reduces the burden on the operator.The inspection level can be selected from 5 patterns (from rank 1 to 5), and can be set according to the inspection accuracy request from the end user.

Product type switching by production control data communication

Product type data is automatically generated by CNC communication from the host. The type and paper size are automatically set, and in the case of repeat orders, automatic inspection is possible without any operation.

Examples of defect inspection

Adhesion of dirt

Blurry print

Missing print

Oil stains

Device configuration example

Inspection specification

Inspection screen Inspection device function

Configuration example

Equipment general specifications

This specification is subject to change without notice

Full inspection width (both front and back)

2200mm(2 cameras)

Inspection width per camera

1160mm

Min. resolution (width)

0.30mm(X)

Min. resolution (length)

0.30mm(Y)

Defects to be inspected

Print misalignment, faintness, dust, dirt, etc.

Inspection method

Full-color image processing method

Inspection interval※distance

1280mm or more※Interval between top of paper to top of paper to be inspected

Number of sheets processed

Up to 250 sheets/min(Details depend on the printer specifications.)

Max sheet size

1280mm×2100mm(Vertical x horizontal)

Number of defect image filings

500,000 images

Data of the product type

Automatic (By production control data communication, product types are created automatically.)

Palletizer section defect display application (option)

It is also possible to display the defect sheet from the number of batches (number of stacks) by receiving data from the host (management device).

PDF digital plate inspection system

(option)A plate inspection is performed by comparing the design (plate) data, which is the master, with the printout.

Camera unit

4096-bit 3-line color line sensor camera, simple dust-proof structure, with board cooler

Lighting unit

Simple dustproof structure

Ccontroller

Simple dust-proof structure, with panel cooler, 17-inch TFT monitor, UPS

Lighting power unit

Built in camera unit

Inkjet printer

A4 color inkjet printer (installed inside the controller)

Power supply

Single-phase AC200V 10% 50/60Hz

Power consumption

4.5KVA

Air purge

none

Ambient temperature

5~50°C

Operating humidity

20~80%(No condensation)