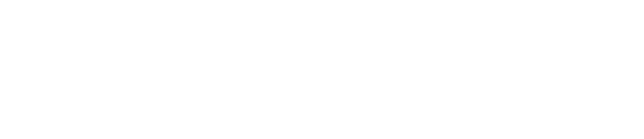

Box-making machines and printing system - Hard Die Cutter

Hard die cutter can punch out even complex designs sharply by advanced computer control, and it is combined with feeder unit, printer unit and control system.

Shinko's unique high-precision hard die cutter system integrates the printing and die-cutting processes into a single process, greatly reduce box-making losses and improving quality.

Specification

| Machine specification | HRD-1420 | HRD-1422 | HRD-1425 | |

|---|---|---|---|---|

| Maximum speed | (sheets/min.) | 200 | 200 | 200 |

| Maximum sheet size | (mm) | 1,350×2,000 | 1,350×2,200 | 1,350×2,500 |

| Minimum sheet size | (mm) | 360×750 | 360×750 | 360×750 |

| Printable dimensions | (mm) | 1,300×1,900 | 1,300×2,100 | 1,300×2,400 | Maximum die cut size | (mm) | 1,250×1,900 | 1,250×2,100 | 1,250×2,400 |

Functions List

| Unit name | Specifications and Functions | Standard equipment | Optional equipment |

|---|---|---|---|

| Feeding Unit | Roll less feeder | ○ | |

| Automatic mechanical return-to-origin device | ○ | ||

| Back guide auto positioning | ○ | ||

| Lead edge auto setting | ○ | ||

| Test paper threader | ○ | ||

| Powerful paper dust remover | ○ | ||

| Sheet jam detector | ○ | ||

| Batch counter | ○ | ||

| Side jogger | ○ | ||

| First batch device | ○ | ||

| Printer (Printing unit) |

Fixed type printer | ○ | |

| Plate cylinder lateral motorized adjuster | ○ | ||

| Plate cylinder automatic origin return device | ○ | ||

| Out of ink warning device | ○ | ||

| Ceramic anilox roll | ○ | ||

| Automatic ink touch device | ○ | ||

| Electric film winding device | ○ | ||

| Doctor blade type | ○ | ||

| Ink bath teflon coating | ○ | ||

| Teflon coating around the ink can | ○ | ||

| Two rolls type (anilox & rubber) | ○ | ||

| Die Cutter | Upper anvil hard roll | ○ | |

| Hard roll for attachment of bottom cutting dice | ○ | ||

| Running register electric setting | ○ | ||

| micron unit display of die cutting pressure | ○ | ||

| Carrying Unit | Carrying belt | ○ | |

| CNC | Centralized control system with touch panel | ○ | |

| Teaching function | ○ | ||

| Uninterruptible power system | ○ | ||

| Communication to the production control system | ○ | ||

| Communication with various inspection devices | ○ | ||

| Large display | ○ |

Features and Functions

Feeding Unit

Test sheet running device

After automatically accelerating the machine, only one sheet is fed.

Sheet jam detector

Sheet jams cause machine damage. A sensor detects jams and automatically stops the machine.

Detection device for misaligned sheet feeding

Detect misaligned sheet feeding and stop feeding.

First sheet setting device (option)

After the lot change, a small stack of sheets is automatically fed to the feeder.

Printer (Printing Unit)

Fixed type printer

Unit fixed type, the plate cylinder raises and downs.

Each unit is connected by the carrying belt, the plate cylinder and ink roll can be raised about 100mm above the sheet pass line. The plate cylinder of the not-in-use printers can be raised for changing printing plate, or prepare for the next order, even while the machine is running. It shortens the setup time significantly, and reduces the work.

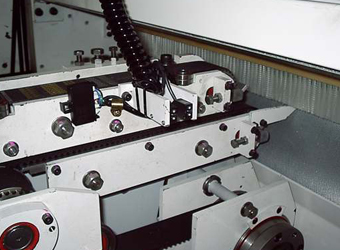

Chambered doctor blade system (Standard specification)

The doctor chamber type is the standard specification. Shinko's unique shape of the chambered doctor blade system ensures sharp and high-quality print images. A 2-roll type for varnishing and solid printing is also available.

Multi-color printing

Depending on the combination of printing units, it is also possible to handle multiple colors from 1 color to 4 colors or more.

Anilox roll (selectable)

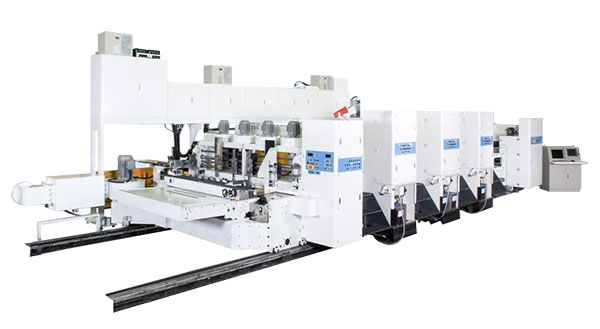

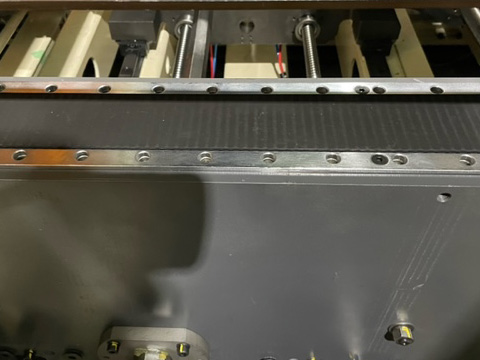

Carrying Unit

Carrying belt system

High-strength timing belts hold the left and right edges of the sheet between the top and bottom to convey the sheet, so even if the sheet is warped, it can be stably conveyed.

Carrying belt center suction

Since the sheet is sucked at the center of the carrying system, misalignment can be prevented.

Hard Die Cutter

Hard Die Cutter

It cuts sheets of any thickness sharply with the best punching pressure, and clearly perform the complex cutting and folding.

For die cutting, we use hard metal type cylinder with high precision cutting further than urethane cylinder.

It can adjust the die cutting pressure in micron unit.

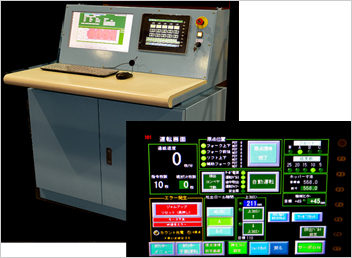

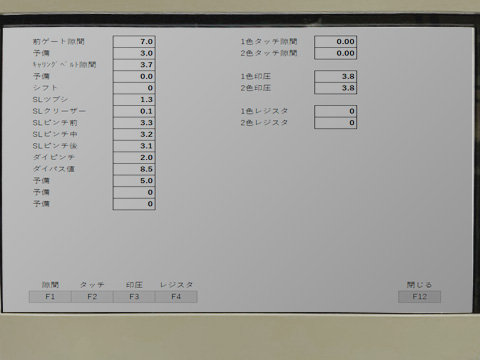

CNC

Main control system

Equipped with dedicated flexo gluer software that has been developed and improved independently, enabling accurate work in a short setting time.

Teaching function

Machine learns the each settings for sheets and products, so resetting for same order is unnecessary.

Large display (option)

The large display shows machine status. (machine speed, set up time etc)

Network communication (option)

Send machine setting data to peripherals, and pass data with various management systems.